Project 1: Box Making | Packaging and Merchandising Design

Project 1: Box Making

Week 5- Week 7

Rafa Maritza Hertrian [0364958]

Bachelor of Design (Honours) Creative Media/ Taylor's University

MER 60104 / PACKAGING AND MERCHANDISING DESIGN

LECTURE

INSTRUCTIONS

PROCESS

We were instructed to choose 2 items that are not commonly packaged in a box.The items that I chose: Crochet yarn ball and socks

Socks Measurements (While Folded)

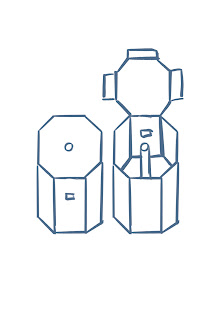

Sketches

Socks Packaging:

Bachelor of Design (Honours) Creative Media/ Taylor's University

MER 60104 / PACKAGING AND MERCHANDISING DESIGN

Crochet Yarn:

Initial Prototype

Before making the dieline, I made the prototype by eyeballing and guessing what it should look like based on my sketches

Below is the chosen sketch and initial prototype of the Sock packaging.

From this prototype, Mr Shamsul suggested finding a cutting pattern that would allow the handle for the socks and the handle for hanging to be one piece, because in this prototype, I had to stick them. This would be inefficient in manufacturing.

Below is the chosen sketch and initial prototype of the Crochet Yarn packaging.

Mr Shamsul suggested making the hole for the string to be key-shaped and also suggested adding a window so that the user can identify the color of the crochet.

Dieline I made the dielines based on the initial prototypes and the comments.

Below is for the Crochet Yarn:

I printed them on a small scale and HVS paper to test if the shape of the dieline is already correct.

Below is the die line for the socks:

After printing them out, I realized a few errors from the dieline. I realized that the handles for the socks packaging do not connect to each other. And for the Yarn ball packaging, the body was gonna be too short for the yarn. Hence, I adjusted the Dielines again.

After checking the shape, I go back and refine the dieline so that the measurements are correct and ready to be laser cut. However, while making this, I was in no place to use laser cutting, so I just made another prototype in the correct size.

From this prototype, several issues need to be addressed: I need to consider the folding measurement because some overlapping parts become untidy. I was also suggested to reduce the size of the window because the thinness of the window decreases the sturdiness of the box. I also did not like how the yarn holder inside the box looks because it is hard to fold the corrugated box into a cylinder. I was suggested to use a used toilet paper roll or shape it into something else.

The outer part of this prototype is too large for the inner part because I created too much space. I decided to make the difference between the inner part and the outer part by 0,5cm so that the inner part cannot slip out. I also need to consider the folding measurement.

Laser Cutting

Final Box Design and Dimension

Yarn ball The idea for repurposing the yarn ball packaging is to create a holder. Yarn balls are usually sold in plastic or carton bands. This makes crocheters have problems with yarn tangling, rolling away, and getting dirty. Hence, they need to put another budget to buy a yarn holder or a yarn winder.

Socks

Typically, socks come in plastic wrappers, hang tags, or plain cardboard bands that are discarded right away after purchase. Customers end up without a suitable method for delivering, arranging, or storing their socks. Socks consequently frequently go misplaced, mismatched, filthy, or broken, particularly when traveling or doing laundry. Customers usually have to pay more for travel pouches, laundry bags, or sock organizers in order to address this.

Typically, socks come in plastic wrappers, hang tags, or plain cardboard bands that are discarded right away after purchase. Customers end up without a suitable method for delivering, arranging, or storing their socks. Socks consequently frequently go misplaced, mismatched, filthy, or broken, particularly when traveling or doing laundry. Customers usually have to pay more for travel pouches, laundry bags, or sock organizers in order to address this.

FEEDBACK

Week 5 Can proceed with the chosen objects

Week 6Next time, make more sketches to show the clients.

Week 7Socks Prototype: Mr Shamsul suggested finding a cutting pattern that would allow the handle for the socks and the handle for hanging to be one piece, because in this prototype, I had to stick them. This would be inefficient in manufacturing.

Yarn ball Prototype: Mr Shamsul suggested making the hole for the string to be key-shaped and also suggested adding a window so that the user can identify the color of the crochet.

Week 8_

Week 9

I need to consider the folding measurement because some overlapping parts become untidy. I was also suggested to reduce the size of the window because the thinness of the window decreases the sturdiness of the box.

REFLECTION

Experience

After doing most of my tasks digitally, it was hard for me to do the prototypes. It was hard for me to not make the lines slanted, and making the measurements correct is also hard. But it was nice to do something without any technology for once. Figuring out a unique packaging for the non-box item was also challenging since not only that it have to be original, but it also has to be functional. It was also frustrating because I had to revise the dieline several times because of incorrect measurements. But the feeling of creating something was definitely fun.

Observation

From this task, I have learned that adjusting your measurements according to the material used to make the box is really important. This is because if you're a thicker and sturdier material, the folded measurements might make the space inaccurate.

Findings

It is important to print out your dieline before making the final product, because sometimes the dieline doesn't look as we imagined. Printing it out first will make us realize the flaws of our dieline and give us a chance to fix it before laser cutting.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Comments

Post a Comment